Excellent quality Piano Action Parts - Safety Equipment – ChinaSourcing

Excellent quality Piano Action Parts - Safety Equipment – ChinaSourcing Detail:

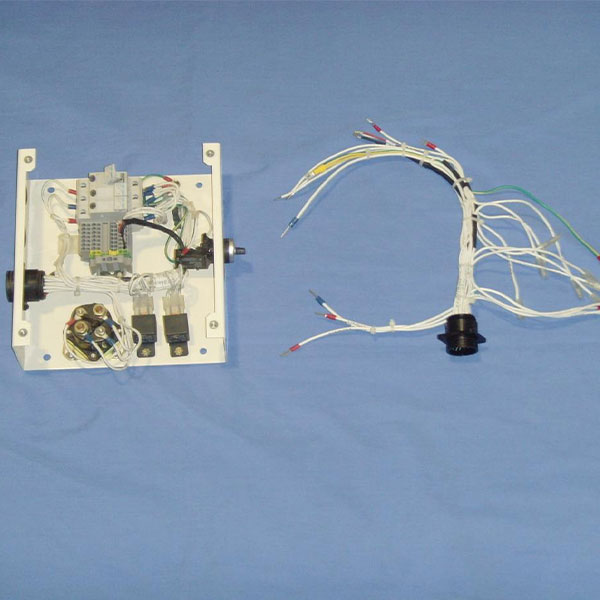

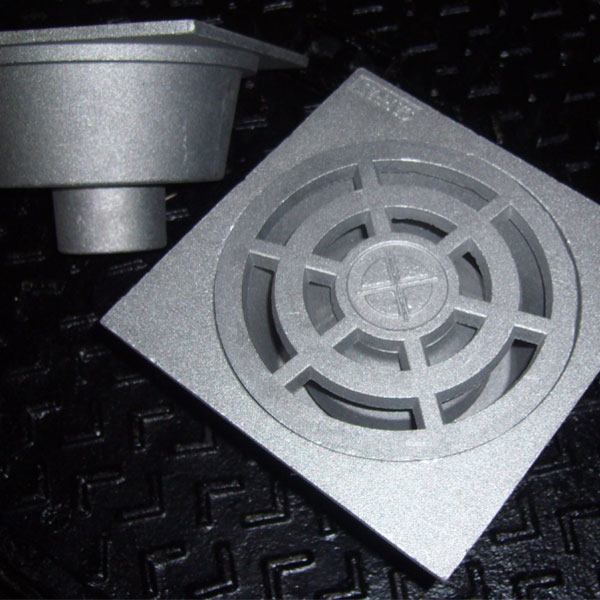

Product Show

Supplier Profile

Established in 2002, located in Yangzhou, Jiangsu Province, HD Co.,Ltd. is expert at precise stamping die, precise sheet metal fabrication, precise machinery and intelligent temperature controlling system.

As an ISO9001 and ISO14000 certificated company, HD has a factory area of 10,000m², a professional staff of more than 100 technical persons, and more than 100 sets of high-end CNC machining equipment. The company’s leading products—precise stamping die—match with CNC machines of many brands such as Tetra Pak, HYVA and Yawei.

Sourcing Case

Established in 1914 in the US, MSA is one of the world’s biggest manufacturers in personal protective equipment and safety monitor industry. The company has world-class labs and complete worldwide service network. The number of employees exceeds 4800.

In 2014, MSA started sourcing strategy in China and chose us ChinaSourcing as their sourcing partner, pursuing cost advantage, good supply chain management, and professional knowledge in Chinese market. After strict screening, we selected HD as our manufacturer for MSA project.

The products of MSA are complicated in structure, and require extremely high precision and high quality. To promoted the project smoothly, our project team visited MSA several times for study and communication. During the prototype development stage, our technical persons worked together with HD and devoted a lot of energy to solve the technical problems. The key problems and our corresponding solutions are as follows:

1.Problem: screw thread match within 1/4 turn

Solution A : Place the protrusion of the part into the groove corresponding to the tooling, tighten the screws.

Solution B: Install and clamp the tooling on the machine, remove the tooling to ensure that the protrusion is always in a fixed position,this also ensures the unity of the screw thread.

2.Problem: Inner hole chamfering tool, angle inconsistent

Solution: Adjusted custom tool.Greatly reduced the fitter work. Good appearance consistency.

3.Problem: A bonding at the screw thread, the work piece size is too small to fit.

Solution: We sent machining finished products to sintering manufacturers for welding before. Now we send machining semi-finished products for welding and then process into finished products. Test qualified.

In 2016, the prototypes passed the test of MSA, and the project entered mass production stage.

Now we supply 4 models of components for MSA, among which IR5500 bracket is the most complicated one. And the annual order volume reaches more than 80,000 pieces. Throughout the whole production and logistics process, we use our methodology, GATING PROCESS and Q-CLIMB, to assure the quality and meet the needs of MSA. As the cooperation has entered a stable stage, we are actively promoting the development of new products.

Sourcing Service

Product detail pictures:

Related Product Guide:

We believe that long time period partnership is a result of top of the range, value added services, rich expertise and personal contact for Excellent quality Piano Action Parts - Safety Equipment – ChinaSourcing , The product will supply to all over the world, such as: Provence, Mumbai, New Zealand, We've a good reputation for stable quality solutions, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.